When ABB contacted us, he had to realize a component of a charging station for electric cars.

This multinational company, leader in the electrical engineering sector, needed it for a project it was making for one of his clients.

The product was to be launched on international markets and would have had great visibility in a short time.

The object had already been designed but the a suitable production technology had to be identified, with the requirement of having some technical and aesthetic features. Then, the production of the product had to be started.

The Challenge

This job had several challenges:

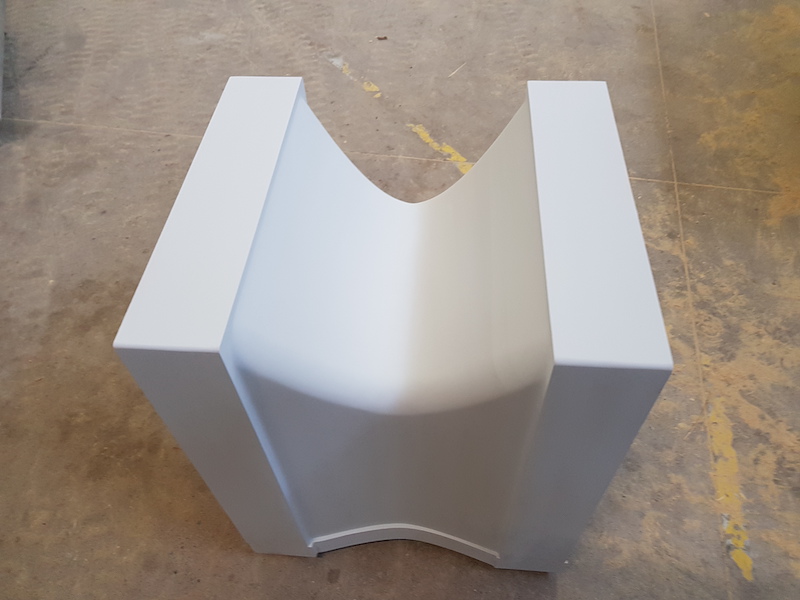

- The easiest technology to use to produce the part was thermoforming. However, the object had a particular geometry that made it complex to use this technology to produce it.

- ABB was also trying to satisfy the requirements of its customer, a company operating in an expanding market such as that of electric mobility at an international level.

ABB counted on us to be able to provide its solutions on time and respecting the estimated production costs.

Execution

The project started from the understanding of ABB’s needs and the correct determination of the final product requirements. After a phase of study and analysis we identified some solutions and proposed them to ABB.

We therefore supported the company in choosing a solution and in developing the project. The collaboration with the company was crucial in this phase.

In the end, together with ABB, we choosed to use the production technology of hand-layered fiberglass. To test this solution, we carried out a first sampling, approved by the customer, followed by series production with the same technology.

We programmed the production according to the customer’s requested quantities, creating the number of molds necessary based on the daily production of each piece.

We have divided deliveries into lots in order to optimize all the production phases and guarantee the customer a constant flow of pieces produced, managing to deliver everything within the timeframe and quantities required.

Project info

Client: ABB

Activities: Consulting, prototyping, production

Objet produced: fabrication of a component for an electric charging station

The final result

For ABB this work was particularly important. The customer needed to meet the expectations required by its clients, to be presented to the public and which in a short time would be used in many parts of the world.

Thanks to our approach and punctuality, it was easy for us to have the customer’s trust. In a project like this, collaboration is the basis of every commercial relationship and it has been the secret that has made it possible to obtain complete customer satisfaction.

Fabrication of a component

Let's get in touch.

Do you need a quote or a consultation? Our staff would be glad to help you. Send us your request, a member of our staff will contact you in a few hours.